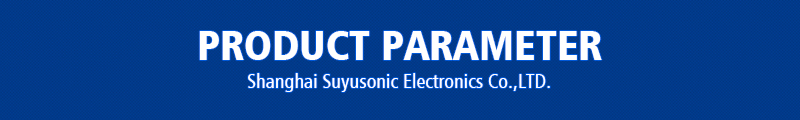

Ultrasonic Food Cutting Workstation

Ultrasonic food cutting workstation make companies in the food industry to increase their performance and improve their slicing operations.

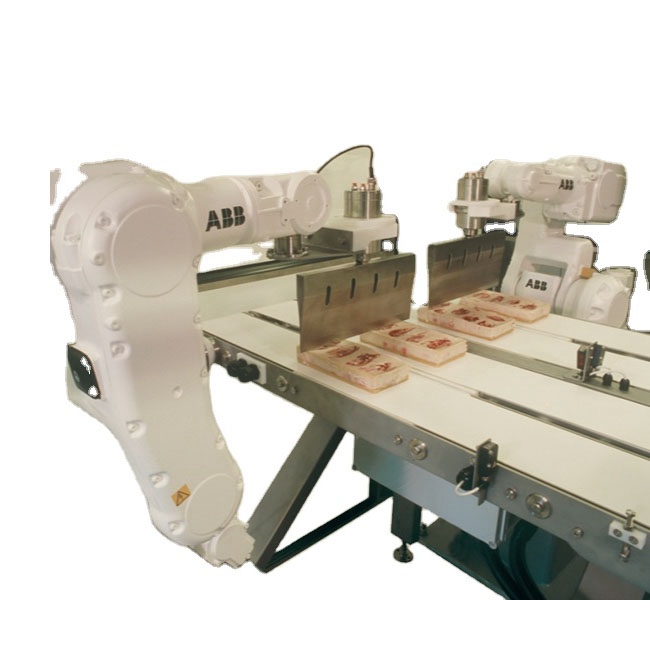

The principle is simple: the edge of the vibrating knife (sonotrode) is set at a defined amplitude (30 to 100 µ) and frequency (20 or 30 kHz) as needed. It creates an acceleration of more than 105 G, which, with the help of a press that moves up and down, cuts food into portions.

Benefits of ultrasonic cutting:

Clean cuts without mess or crushing,

Compatible with soft, sticky and crumbly foods,

Self-cleaning blade,

Food does not adhere to the sides of the blade, thus preventing layers from smearing into each other,

Extremely thin, uniform layers possible with a level of tolerance that is yet unattainable with other methods,

high throughput,

Zero crumbling and less product loss,

Much safer than all other conventional cutting methods,

Cuts through hard ingredients (walnuts, pistachios, olives, raisins, etc.) without moving them from place.