Following the previous article, we will introduce the second welding methods of thermoplastics today.

The methods of softening and completing welding by mechanical movement are:

● According to the motion track, it can be divided into linear type and rotary type

The linear type can be used for the welding of straight welds and plane welding, and the rotary type can be used for the welding of circular welds. Using the friction heat generated by the two parts under pressure during the friction process, the plastic in the contact part is melted and softened, aligned and fixed until it is solidified.

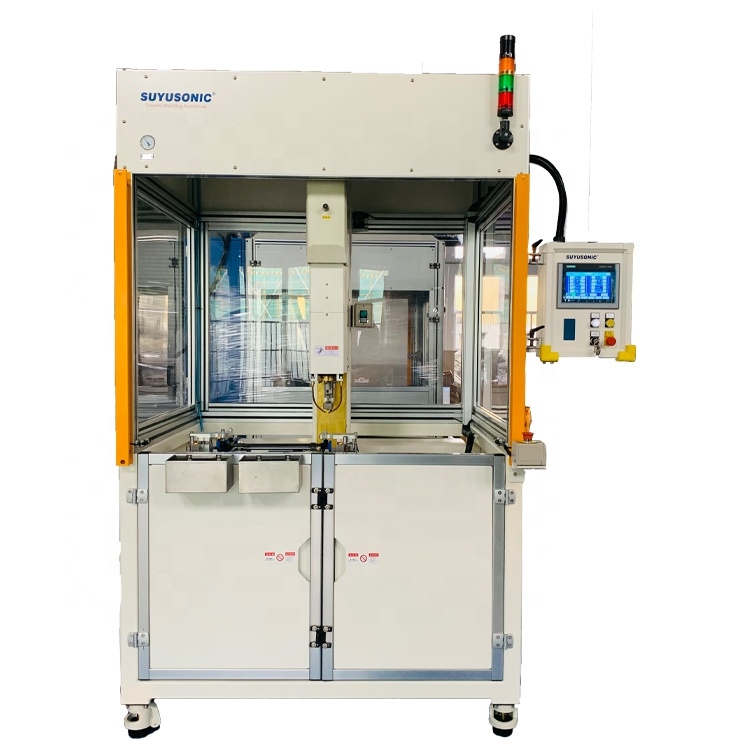

● Ultrasonic welding

Ultrasonic welding is the use of high-frequency mechanical energy to soften or melt the thermoplastic at the joint. The connected parts are fixed together under pressure, and then undergo ultrasonic vibration with a frequency of usually 20 to 40 kHz. The transducer converts the high-power vibration signal into corresponding mechanical energy, which is applied to the contact interface of the plastic part to be welded. Violent friction at the joint of the weldment, instantly generates high heat, so that the molecules alternately fuse, so as to achieve the welding effect.

The ultrasonic welding process is very fast, the welding time is less than one second, and it is easy to realize automation. It is widely used in various industries such as electronics, electrical appliances, auto parts, plastic toys, stationery, daily necessities, handicrafts, and cosmetics etc..

● Motion welding

Motion welding is a fully automatic welding process that requires special welding equipment. Once the correct welding parameters are determined, the operator can stabilize production. Its advantages are: fast, flexible, stable welding process, no flux or shielding gas, no harmful gas or slag, and the welding quality of the product has guaranteed.

www.suyuplasticweldingmachine.com